Jasper

What is the purpose of the non return valve in the fuel tanks? I am currently fitting another corsa Fuel Tank to my SP5 (Later version rather than the earlier version I was running), and one fitting has the valve in and the other doesn't, what is the purpose of the valve? What would happen if you did not run one?

Cheers,

Jasper

MarkT

Jasper- are you talking about the check valve on the return side- I assume that it is to prevent bleeding down of the fuel pressure so you do not have to build it back up when you restart the motor.

Jasper

MarkT wroteJasper- are you talking about the check valve on the return side- I assume that it is to prevent bleeding down of the fuel pressure so you do not have to build it back up when you restart the motor.

Yes mate.

griff851

It also works in conjunction with the fuel pressure regulator. The fuel pressure regulator is a sprung valve that opens up and ports excess pressure to return, suppling a stable pressure to the injectors, that is a constant known to the ecu. Included is the back pressure provided by the reversion or check valves spring tension in the return line.

For example. Regulator opens at say 10 bar,(no check valve),but the check valve won't crack until 2 bar. Effectively the pressure available at the injector would be 8 bar.

Apparently the 916 race boys of old, use to increase fuel pressure by changing the check valve spring for a a heavier one. I imagine they did this because the later model pressure regulator doesn't have a bung in the back to access the regulators tension spring like the earlier models.

Now because injectors are fuel cooled, if you don't have a reversion valve in line, at start up there would be not enough pressure in the line to force fuel through the injector for cooling and lubricating it. Of coarse you could say well the pump runs initially and that should provide enough pressure, but if the fuel line is empty, that run isn't enough.

If you've ever done a start after throttle body change or something, you'll notice it takes a couple of cycles of the ignition before you here the trickle in the tank.

Injectors are just a normal closed solenoid powered needle valve. 50hz being cycling 50 times a second. The solenoid gets hot and you run the risk of thermal expansion jamming the needle.

The other issue is if you have and adjustable early type regulator, does it have enough adjustment to cover the lack of reversion valve to give you the line pressure needed.

I just took the old one out of my tank and stuck it in line under the throttle bodies. The early RR tanks had it built into the return line quick disconnect fitting on the tank.

My opinion, you need one. It would be a lot easier than all the fuel line pressure testing you would have to do to get the right line pressure. Not to mention finding the right pressure regulator.

Jasper

Awesome reply Griff, thanks. So my next question is, is there an inline check release valve available that does the job of the intank/quick release fitting valves, with the correct pressure? There is a reason for my questions: I don't want a check valve on the tank (either as it is is on a standard tank or part of the QD fitting).

Cheers,

Jasper

griff851

Does your old tank have one. Unscrew it, it should have barbs both ends. Stick it in the return line fuel hose, anywhere you choose.

As to an after market one. I have no idea, never pressure tested one to find what it's opening pressure is.

griff851

Here’s one at 12 lbs, whether it suitable, I have no idea. It unscrews, so you might be able to find the right size coil spring.

Be a handy thing to find out, something like this would be a possible quick fix or check to have laying about should a performance drop off occur in the original. Ball bearing or seat might be corroded or beaten to death through cycles.

Jasper

griff851 wroteDoes your old tank have one. Unscrew it, it should have barbs both ends. Stick it in the return line fuel hose, anywhere you choose.

As to an after market one. I have no idea, never pressure tested one to find what it’s opening pressure is.

Yes, That's what I am thinking.Thanks. I have this in my spares, so will give it a go!

https://www.ebay.co.uk/itm/283018073411

Mr.R

I think that Griff has "over thought" this, I think the valve in the road bikes is just a simple non return valve, to stop the fuel from running out when you disconnect the fuel lines.

The pressure over the injectors is maintained by the pressure set via the adjustable fuel pressure reg', anything after that has closed can't effect the pressure over the injectors.

When I changed out my OEM tank for a ITE Fuel Cell there wasn't any threaded fitting to fit the OEM part, so I just ran the supply to the internal pump and the return to the tank and...

There wasn't any noticeable difference in performance???

When you turn on our bikes the ECU fires up the fuel pump for a set time, which is enough to build up the pressure over the injectors before you actually fire up the ignition, so they shouldn't be running dry ever.

When I set up my bikes I fit an in-line pressure gauge in the supply line, then with the motor turned on set the adjustable pressure relief valve to the required pressure. After this with the motor running the fuel pressure doesn't noticeably alter, because the pressure is governed by the regulator.

Am I missing something here?

Steve R

Jasper

Hi Steve,

I am on about the ones in the Corsa QD connectors, but am presuming they do the same job?

I thought the same as you, stop the fuel running out when the fuel pipes are disconnected, but Griffs response does make sense, as does yours!

griff851

Yes Steve, I do over think everything, then arrive at KISS. 😁

The issue came up when I changed over to the RR tank back in 06/07 Marvin very kindly made up some Corsa tank connectors for me. One has a the check valve the same sort of size as the original reversion valve. in it the other doesn’t. Both have male fittings coming out of the tank. The female quick disconnects which close off when disconnected are on the fuel lines. When you take the tank off, with their set up fuel leaks from the pump side but not the return side until the line from the pump to the tank fitting is empty. Which is odd considering in the pits you’d be looking to reduce fire hazard if you need to do something requiring tank off on a hot bike. Why didn’t the just fit the normal males directly into the tank as they seal off when disconnected.

The reversion valve is after the pressure reg, so the pressure reg is holding fuel in the injectors circuit in theory.

So you think ok, they stuck in the reversion valve to stop fuel siphoning out until it reaches the degasser level, makes sense. Except for the bit where why is there this ubeaut reversion/check valve there when the male quick disconnect fitting would do the same job.

Then when you look at later models there is once again in the pump pack a ubeaut thing in the return line where a simple quick disconnect would have done.

So, I took out the corsa style fittings and made up some tank fittings to hold female quick disconnectors, thus solving the fuel coming out of the pump line issue. Also saving Marvin’s beautiful fittings in case the next owner wants a more original fit. (They are preserved in oil) Then decided that the reversion valve must have some purpose, so I stuck it in the return line with a bracket to the throttle body frame. The KISS part, just stick it back in.

So what is the point of this valve, well I can only speculate. Our Italian mates do things for a reason. Did they know the new regulators coming out didn’t have the regulator adjustment access and needed away for a bike being set up in race trim to have fuel pressure adjustment? Is it there to to reduce loading on the pressure regulator sealing seat to increase service life of the regulator?

Was it easier to just change the spring on the RR tank reversion valve, rather than spend hours looking for the pressure reg bung after you drop it trying to fit it back in, don’t know.

All I know is that pressure on both sides of a pressure regulator add up to give you injector line pressure.

One day I might pull out the reversion valve and check out what pressure it cracks at. I seem to remember trying to blow into with my mouth, but can’t remember whether it cracked, so there’s a few psi in it at least.

Jasper

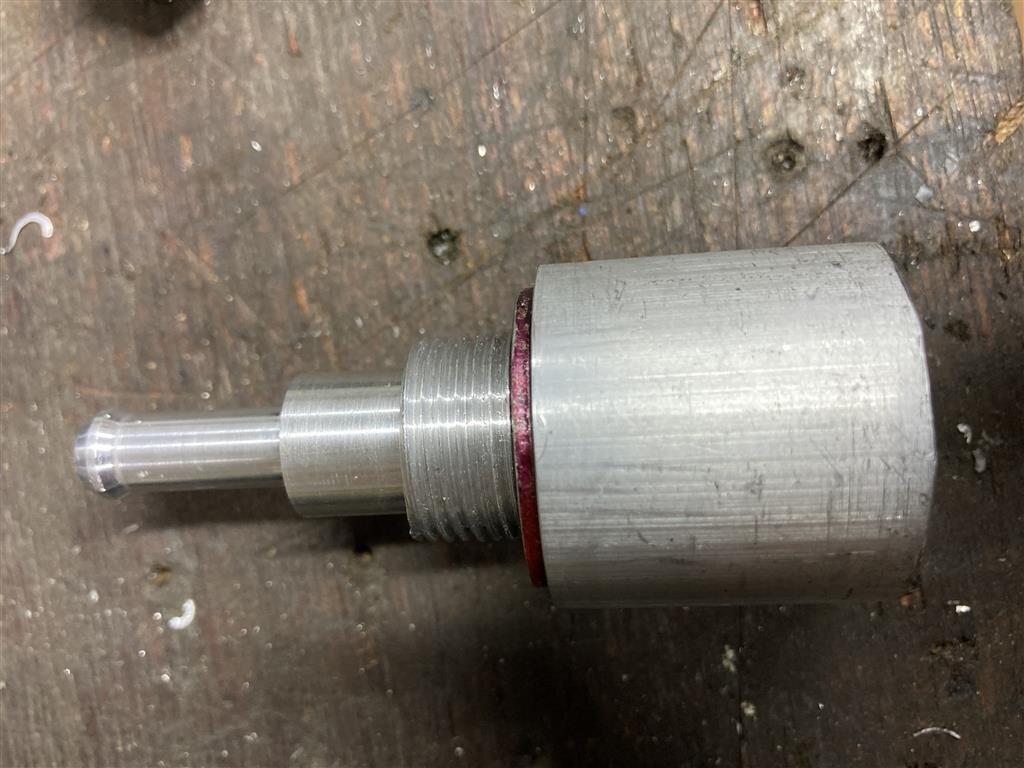

So, I have made 2 these so far, screw cutting the thread, the valve was always going to be a problem, so I am fitting the Sytec inline valve inside the tank. I will use the valve as it comes with the spring from the OEM, so at least I have a semblance of continuity!

marvin

I have made quite a few of those in the past . I found some small balls that worked and springs as well. I have no idea what pressure they "popped" at. I also anodized them black, almost exact copies of the OEM units that I borrowed from MarkT

Jasper

marvin wroteI have made quite a few of those in the past . I found some small balls that worked and springs as well. I have no idea what pressure they "popped" at. I also anodized them black, almost exact copies of the OEM units that I borrowed from MarkT

Yes, I still have those Marvin. Due to a completely different issue, I cannot use them!