All done.

Stripped all bearings and pinch nuts before I started.

Took it to the anodisers to strip first (hence all ferous parts removed) - anodising grows on the surface but also into the surface. It's important you strip original anodising first or you run the risk of not going deep enough with your sanding and when it gets anodised it doesn't - anodising doesn't grow on anodised finishes.

I took out all damage and scratches with 800 grit wet and dry and finished off with green then red scotchbrite pads to get the finish balanced between matt and shine.

All sanding was liner with the direction of the arms. The bits in betgween took some finishing with scorchbrite to get a consistent finish.

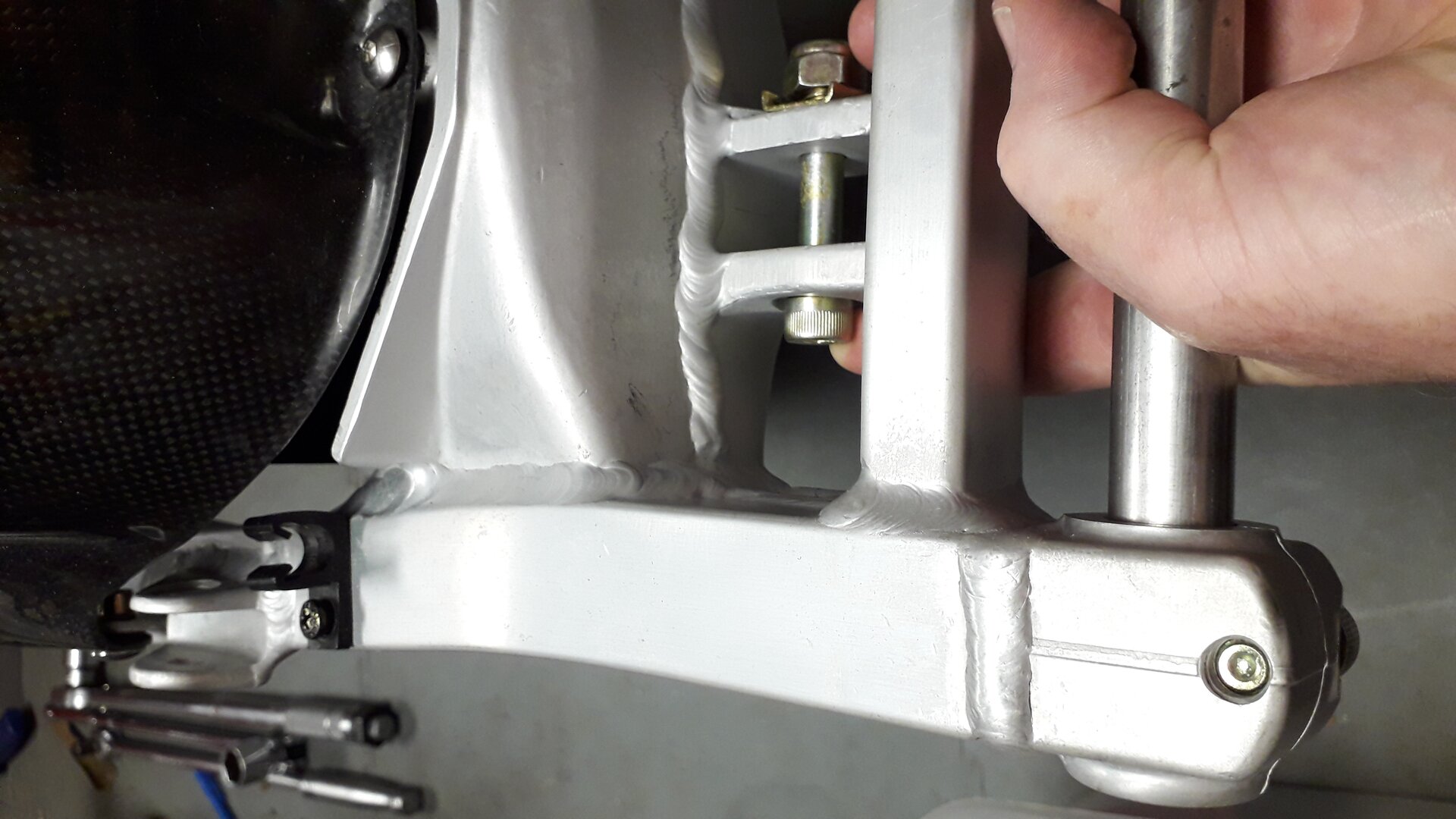

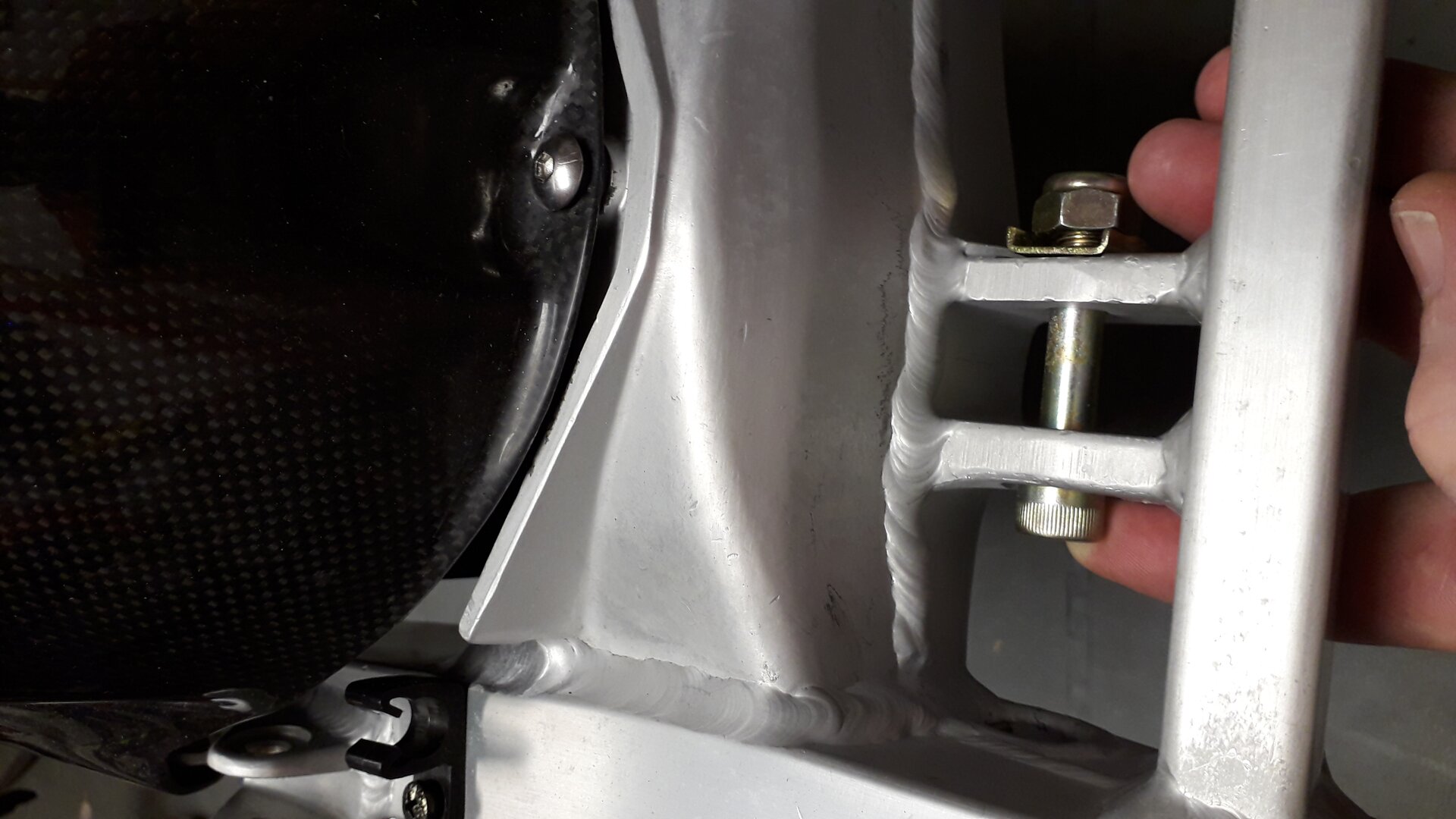

Pictures are of natural anodised finished item.

It is different to the original finish as it lacks that high reflective character.

Anodiser said it's almost impossible to get that original finish in EU as the chemicals necessary are prohibited these days.

All anodising by Daventry Metal Finishers

http://daventrymf.co.uk/